Environmental Control System

Electrical and Environment Controller

Environment terminal control system to control such environmental factors as temperature, humidity and air supply inside the house, making breeding much more efficient and convenient;

The control system is mainly used to control the enclosed room temperature in the set temperature range. Because the temperature of the closed layer chicken house needs to be constant at 22-29 degrees Celsius, so that the hen will have the best body feel and comfort, egg production rate will reach the highest. Our customers are in different regions in the world, according to it, we need to make different temperature control solutions. The temperature control system of the house is a vital part of the modern large-scale chicken farm using the automation equipment to feed the laying hens;

Precise control technology can effectively save feed and reduce energy consumption;

The operation is simple and easy to manage and can manage multiple chicken houses at the same time, real-time monitoring;

The temperature and humidity are automatically adjusted and alarmed to reduce the rate of death of chickens and greatly improve the economic benefits of users.

Draught Fan

HEFU’s fans, featuring stable quality, sufficient air volume, energy conservation and reliability to completely satisfy clients’ breeding needs which is used to ventilate and cool the animal husbandry farms. When the fan is started, the opening mechanism drives the shutters to open in linkage. When the power is cut off, the shutters will be closed under the action of tension springs. The operation of the fan promotes the air to flow and to ventilate and cool the space;

Imported belt is used, which has strong tensile strength;

The hot-dip galvanized sheet that meets the requirements of national standard is used, with a galvanized layer of 275 g/m2 and strong corrosion resistance;

The fan blade is made of 430 stainless steel which has smooth surface and without accumulated dust;

Flange plates are widened to improve the strength;

Suitable for the ventilation and cooling of chicken coops, effective discharge of waste gas in the shed;

Centrifugal opening mechanisam, so that the blinds are fully 90 degrees open.

Cooling Pad

HEFU’s cooling pad with characteristics: favorable cooling, long service life and easy maintenance.;

Cooling pad is mainly used for poultry house cooling and humidification. The mode of “cooling pad-negative pressure fan” is mainly used and the working principle goes like that: The cooling process of the cooling pad is completed in its core“cooling pad paper”. When the outdoor hot air is sucked into the cooling pad paper covered with cooling water by the fan, the cooling water will be transformed from liquid to gaseous water molecules, which absorb a large amount of heat energy in the air, so that the temperature of the air drops rapidly. After being mixed with indoor hot air, it will be discharged outdoors by the negative pressure fan;

Our cooling pad system comprises cooling pad-aluminum alloy frame and PVC frame with water trough cool pad;

Cooling pad-aluminum alloy frame uses aluminum alloy as frame material which is practical, good-looking and has high strength;

PVC frame with water trough cool pad uses PVC water trough which has water storage function, so there is no need to build additional water pool;

Main water inlet piping of cooling pad system is equipped with filter of high fineness, so as to prevent the spray pipe and the cooling pad paper from being clogged by impurities in water.

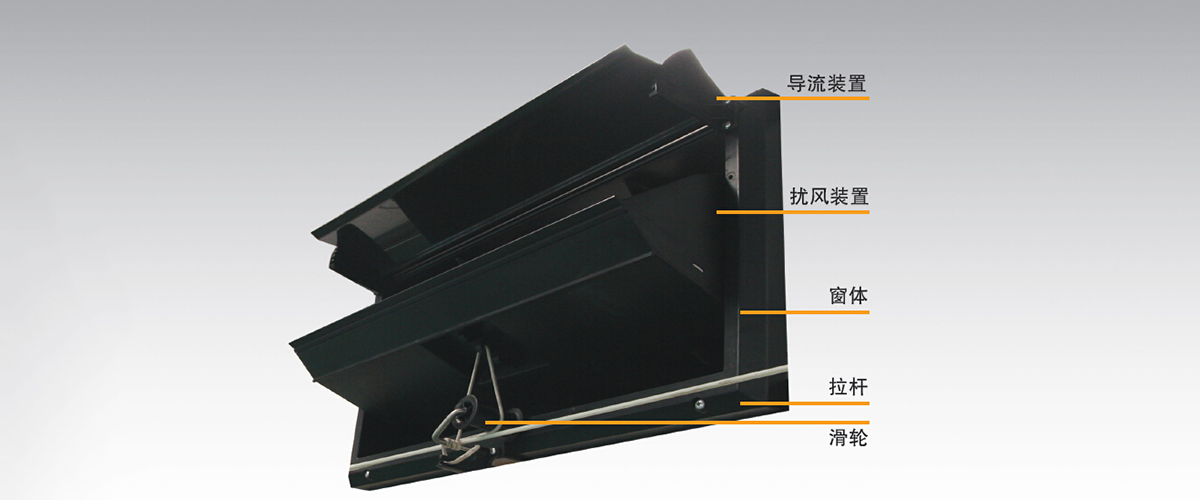

Air Inlet

Inlet window can adjust the area of air intake, control the wind speed and ventilation volume of the house, to achieve the ideal ventilation effect;

The air inlet is opened by drive traction and closed by spring tension;

The air inlet is designed with groove rib occlusal structure which has good sealing effect;

The air inlet is equipped with a guide plate which can be adjusted to different opening angles to ensure that the air inlet is blown into the center part of poultry house.

PVC Panel

Panel door is installed at the air inlet of cooling pad system. It can be closed in winter for heat preservation and open ventilation in summer to change wind direction and to control wind volume;

Good thermal insulation performance, effective thermal insulation;

Good sealing performance, no leakage of wind after closing;

Good air guide effect, gable insulation door can be opened up to 90 degrees, no ventilation dead Angle.

Light System

Lighting System plays an important role in poultry farming;

Healthy and scientific lighting system can provide stable and sufficient lights which reduce chicken stress to ensure much higher egg laying rate and meat production rate;

We have various lamps for different kinds of poultry farms;

With our different lighting system design, we can ensure light will reach all necessary place poultry farm needed. Sufficient lights will benefit to poultry growth;

The smart dimming system is independently developed for broiler and duck breeding. It can control the brightness, time and brightness change accurately to provide a suitable light environment for broilers and ducks.